Textile Adviser CARDING PROCESS, OBJECTIVES OF CARDING, STRUCTURE OF CARDING MACHINE, WORKING

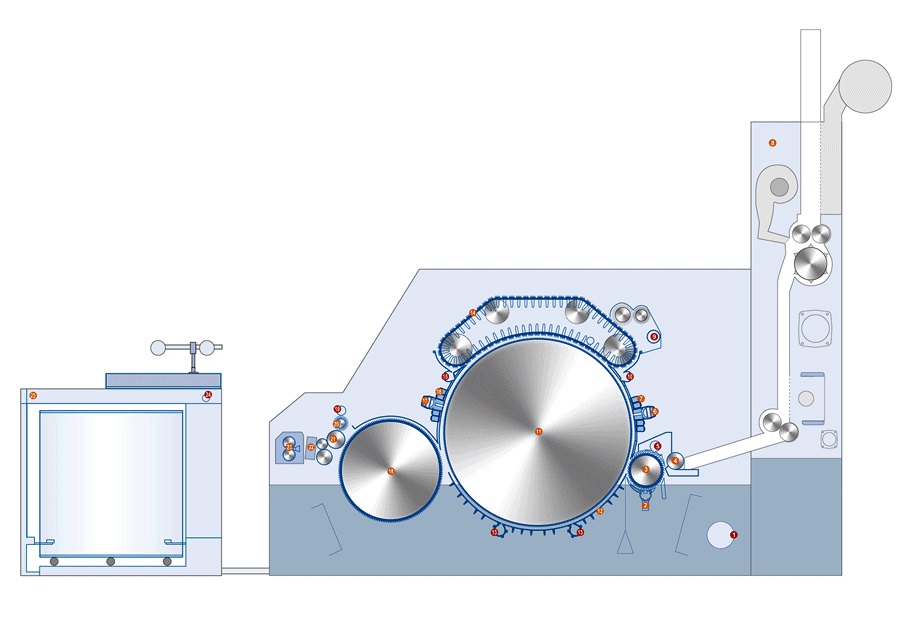

Rieter HP Card C 75 Machine Data. There are carding machines that are able to produce 100 kg/hr card sliver or more. We call them HP card. HP stands for High Performance or High Production. Rieter C 75 is a HP card. This is one of the state-of-the-art machine. Here some data are provided regarding the machine.

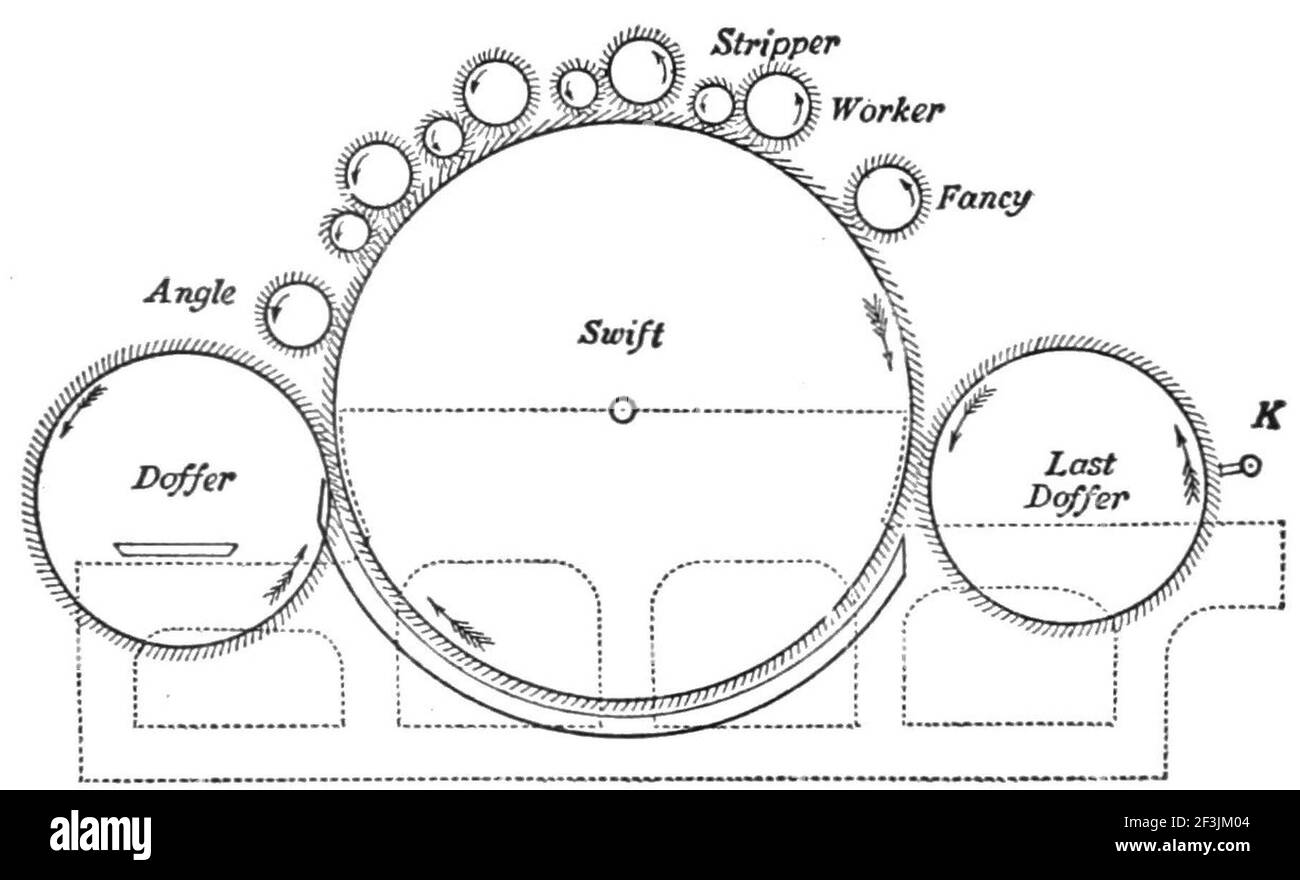

Working parts of a carding machine Stock Photo Alamy

Gearing Calculation of Carding. Raw cotton fibers are transformed into a continuous and uniform web through the use of a cotton carding machine in the initial stages of textile processing. Two critical aspects of cotton carding are discussed in this study: motion transfer diagrams and draft calculations. A motion transfer diagram reveals the.

Carding Machine Production YouTube

Doffer is a revolving cylinder, or a vibrating bar, with teeth, in a carding machine, which doffs, or strips off, the fiber from the cards. The doffer is a small cylinder made and clothed like the main cylinder. Metallic clothing is used for the doffer. The function of the doffer is to collect the cotton from the cylinder in a uniform fleece.

CardingMachineDiagram Barnhardt Purified Cotton

A carding machine is used to process raw material after it exits the blow room. A pipe duct (1) supplies raw material into the feed chute (2) of the card. Approximately 500-900 ktex batts are formed in the chute. Material is transported from this batt to the feed arrangement (4) by a transport rollor (3).

Gearing diagram of jute breaker carding machine YouTube

The common structure of a carding machine is illustrated in below schematic diagram:. The uniform fibres mat coming out from the chute feed system is supplied to the carding machine with the help of a feed roller. The linear density (weight per unit length) of the fibre mat typically ranges from 400 to 1000 grams per metre (K tex).

Carding YouTube

Carding action: If two closed surfaces have opposite wire direction and their speed direction is also opposite to each other, then the action between two surfaces is known as carding action. Opening to individual fibers and neps removal is done by this action. Action between cylinder and flat. Wire direction opposite. Speed direction opposite.

Textile Adviser CARDING PROCESS, OBJECTIVES OF CARDING, STRUCTURE OF CARDING MACHINE, WORKING

Rashid et al. (2019) within the scope of their study, five different carding machine flat speeds (200,240,280,320 and 360 mm/min) produced card slivers with Ne 0.110 number. They produced Ne 24/1.

Carding machine Cormatex

Join for free. Download scientific diagram | Schematic Diagram of Carding Machine [13]. from publication: Effect of Variation in Different Mechanical Setting of Draft Change Pinion in Trutzschler.

Carding Process Cylinder Flats Doffer Sliver formation Part 4 TexConnect Explained

Carding Machine Diagram. Note the feed matt or batt is fed in from the left side. The fibers are carried around the large main cylinder over the top by the stationary flats and removed as the card web on the right where it is deposited on a conveyor that leads to nonwoven bonding.

Ramella Carding machine for fiber mills and textile laboratories

The speed parameter of carding machine changes the fiber behaviour in next process. Today, to achieve better production and quality of delivered material, we need to optimise the speed parameters.

A waterdriven carding machine

Carding is a mechanical process that breaks up locks and unorganized clumps of fiber and then aligns the individual fibers so that they are more or less parallel with each other. Carding can also be used to create blends of different fibers or different colors. Carding plays a crucial role in all spinning cycles particularly in the woolen spinning cycle, in which it incorporates different.

Roller carding machine scheme. Download Scientific Diagram

Figure 2: Material passes diagram of carding machine. The doffer takes the fibres from the cylinder in fleece form. From the doffer, the fleece runs through the doffing roller, crush rollers and tongue-groove rollers. These rollers scanned the cross-section / thickness of the carding sliver. The recorded results are compared with the set target.

Roller carding machine scheme. Download Scientific Diagram

Introduction Carding is a mechanical process that disentangles, clean and intermixes fibers to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibers between differentially moving surfaces covered with card clothing. In carding, fibers are opened to more or less single fibers.

Diagramma Illustrativo Di Uno Scribbler/carding Machine Fotografia Editoriale Illustrazione di

Carding Machine is used for fibers, which need to pass a sequence of processing to get yarn. This is the first step of spinning process. Spinning of textile fibers may be carded and cotton is the most common products all over the world for spinning process is completely different from textile fibers spinning methods. The main task of carding.

FB1233 CARDING MACHINE Sino Machine GroupCOTTON AND FIBER BLOWING CARD

Diagram of Carding Machine: Figure-01: Carding machine. Main Parts of Carding Machine: Lap stand: It is a lap pin where wounded lap gets support. Lap Unwinding roller: It is used for unwinding lap from lap pin for further processing. Its diameter is inches. Feed Plate: Used for feeding fiber in the machine.

A diagram of different parts of a carding machine. Download Scientific Diagram

The machines used in the carding process are generally two types-. The breaker card. The finisher card. Breaker Carding:- In different jute mills the carding operations has been carried out in two ways: Hand feed breaker carding. Roll feed breaker carding. The material after piling more than 24 hours is used hand feed breaker where the material.